Stamping presses are mainly used for the production of sheet metal. Stamping presses are metalworking machine tools used to cut or shape metal by deforming it using a die. They are capable of punching, forming, deep drawing, blanking, riveting and fine punching. In simple terms, this machine tool can be thought of as the modern-day equivalent to a hammer Read More…

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At Eagle Press & Equipment Co., we are dedicated to engineering and manufacturing high-quality hydraulic presses that meet the diverse needs of industries worldwide. With decades of expertise, we have built a reputation for delivering presses that offer superior performance, reliability, and precision, supporting everything from small-scale production to heavy-duty manufacturing applications.

At AIDA-America Corp., we are dedicated to advancing the manufacturing industry through our expertise in hydraulic press technology. We design and build presses that deliver precision, efficiency, and reliability for high-volume production environments.

At Hydraulico Inc., we have built our reputation as a leader in hydraulic press engineering by combining decades of expertise with a passion for innovation and precision. We design and manufacture high-performance hydraulic presses that meet the demands of industries ranging from automotive and aerospace to metal forming, appliance production, and advanced material processing.

More Stamping Press Manufacturers

Comprehensive Guide to Stamping Presses: Types, Components, Applications, and Buying Considerations

Stamping presses are vital machine tools in the manufacturing industry, used for shaping, cutting, and forming metal and non-metal materials into precise components. As the backbone of high-volume production in sectors such as automotive, electronics, appliance manufacturing, aerospace, and more, understanding the capabilities and benefits of stamping presses is crucial for businesses seeking to optimize their fabrication processes and achieve quality, cost-effective results.

Are you looking to invest in a new stamping press, upgrade your metal stamping equipment, or simply learn more about press machinery? This guide covers essential details about stamping press components, their working principles, the various types available, real-world applications, advantages, and key factors to consider when selecting a stamping press supplier. For buyers, engineers, and procurement specialists, this resource is designed to answer your most common questions and help you make informed decisions for your manufacturing operations.

What Is a Stamping Press?

A stamping press, sometimes referred to as a metal stamping press or press machine, is a mechanical or hydraulic device used to shape or cut metal sheets into desired forms using dies and specific amounts of force. Stamping presses are central to many metal forming processes, including blanking, punching, embossing, bending, flanging, and coining. The choice of press type, tonnage capacity, and automation level can significantly affect production speed, part quality, and tooling longevity.

Components of Stamping Presses

Understanding the main components of a stamping press is essential when evaluating metal forming solutions or troubleshooting equipment. The core parts include:

Bolster Plate

This robust component is mounted atop the press bed and serves as the stable foundation for the lower section of a die set. Constructed from heavy-duty steel, the bolster plate absorbs significant forces during stamping operations. In high-tonnage presses, such as those used in automotive stamping lines, integrated die cushions within the bolster plate provide precise blank holder or counter draw forces—crucial for deep drawing and complex forming tasks. For single-acting presses, these cushions are especially important to maintain material integrity and part accuracy.

The Ram/Slide

The ram, also known as the slide, is the reciprocating part of the stamping press that mounts the upper die. It moves vertically to deliver force to the workpiece, shaping or cutting it against the stationary bolster and lower die. Quality ram and slide guidance systems—such as 8-point full-length guides, 6-point square gibs, or 4-point V-gibs—are integral for maintaining die alignment, reducing wear, and extending tool life. Efficient ram operation ensures smooth feeding of materials and accurate die contact, which are critical for high-precision stamping.

Frame

The frame houses the press’s structural elements and absorbs the forces generated during the stamping process. Stamping press frames come in different configurations, including C-frame, H-frame, and four-post designs. The frame’s rigidity, material, and geometry all impact press stability, load distribution, and operational safety.

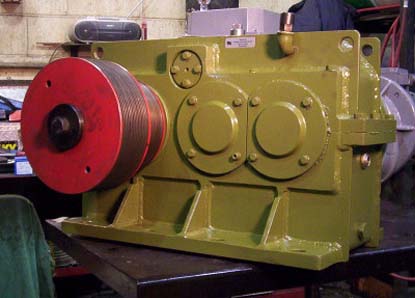

Drive Mechanism

The drive mechanism powers the ram’s movement. Mechanical presses typically use flywheels, clutches, and crankshafts, while hydraulic presses rely on pumps, cylinders, and valves. Servo-driven presses employ electric motors and programmable controls for precise force and speed management, making them popular for complex or high-speed operations.

Control System

Modern stamping presses are equipped with advanced control systems, including PLCs (programmable logic controllers), HMI (human-machine interface) panels, and safety interlocks. These systems manage press motion, force application, stroke settings, die protection, and safety features, optimizing production efficiency and operator safety.

The Working Principle of Stamping Presses

How does a stamping press work? The fundamental principle behind stamping presses—whether mechanical, hydraulic, or servo-driven—lies in the controlled application of force to deform or cut a workpiece using a die set.

Hydraulic stamping presses, for example, operate based on Pascal’s law. Liquid pressure is controlled within a chamber using valves, enabling the operator to increase or decrease the force applied by the ram. When the hydraulic fluid’s pressure is adjusted, the piston and ram move accordingly, delivering precise, repeatable force to the die and workpiece. This allows for the application of immense tonnages, with some hydraulic presses achieving forces of 75,000 tons or more.

Mechanical stamping presses use stored rotational energy in a flywheel, which is released via a clutch and crank mechanism to drive the ram. This setup is known for speed and efficiency in high-volume runs, but force output is highest near the bottom of the stroke. Servo presses use electric motors for unparalleled control of ram speed, dwell, and force, making them ideal for intricate and variable forming applications.

Types of Stamping Presses

Metal stamping presses come in several designs to suit different production requirements, part geometries, and material types. The most common types include:

Bench Presses

Bench stamping presses are compact, affordable, and easy to integrate into small-scale manufacturing environments or assembly lines. Their tonnage capacity typically ranges from 3 to 50 tons, making them ideal for light-duty stamping, prototyping, electronics assembly, and precision component production. These presses support both single-cycle operations and automated manufacturing cells.

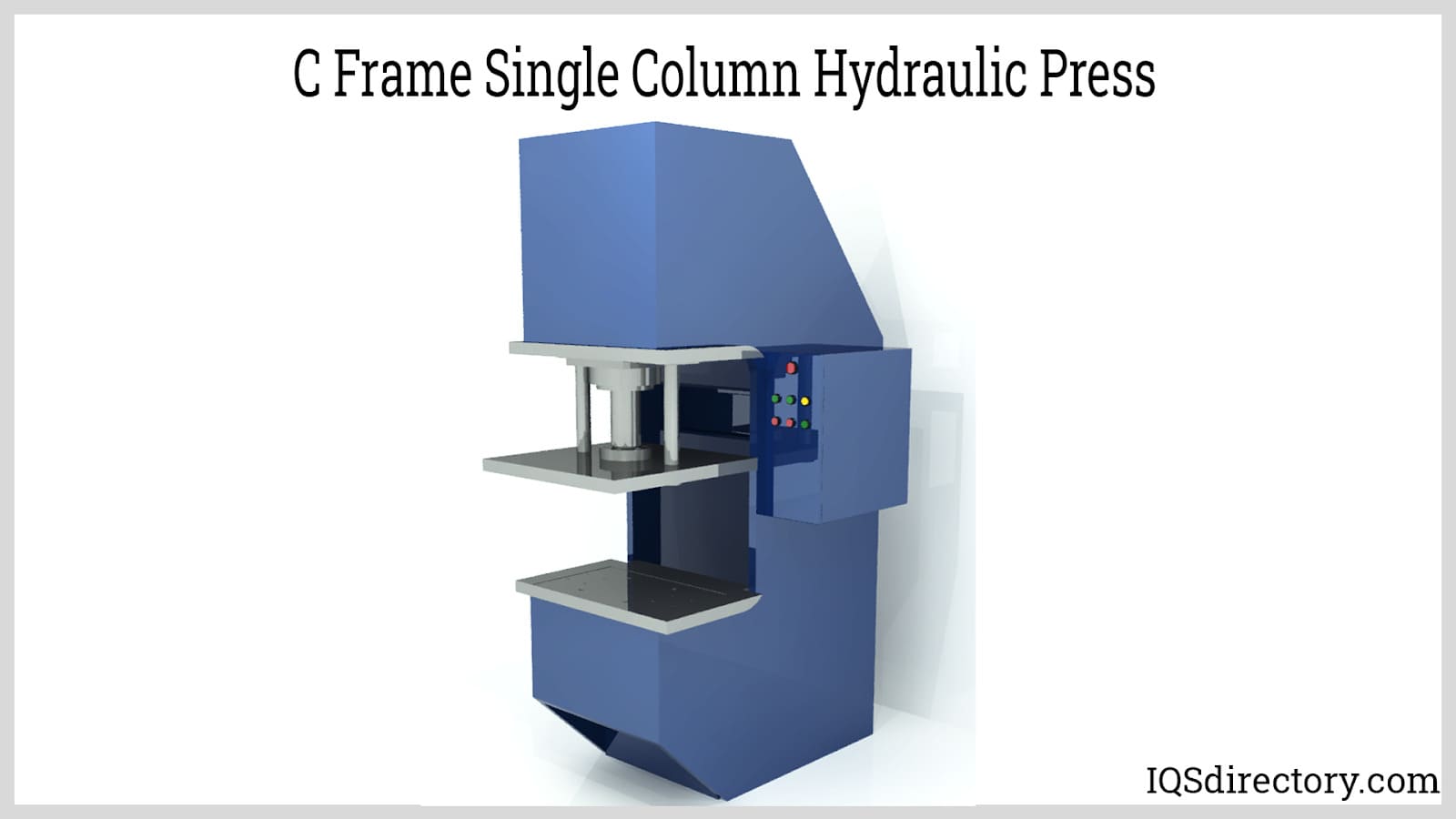

C-Frame Presses

C-frame stamping presses are named for their distinctive “C” shaped frame, which provides open access to the die area from three sides. Available in capacities from 10 to 500 tons, C-frame presses offer versatility for medium to heavy-duty stamping, punching, blanking, and forming. Their open-front design makes die changeovers and part removal quick and efficient, supporting multi-shift production in automotive, appliance, and general metalworking industries.

Four-Post Presses

Four-post (or four-column) stamping presses are engineered for heavy-duty, continuous production. The four robust columns precisely guide the moving platen or slide, ensuring perfect parallelism and minimizing deflection or “lean-back” during high-force operations. Four-post presses are commonly used for deep drawing, high-tonnage blanking, large-part forming, and applications demanding consistent die alignment and repeatability. These presses are prevalent in automotive, appliance, aerospace, and industrial fabrication sectors.

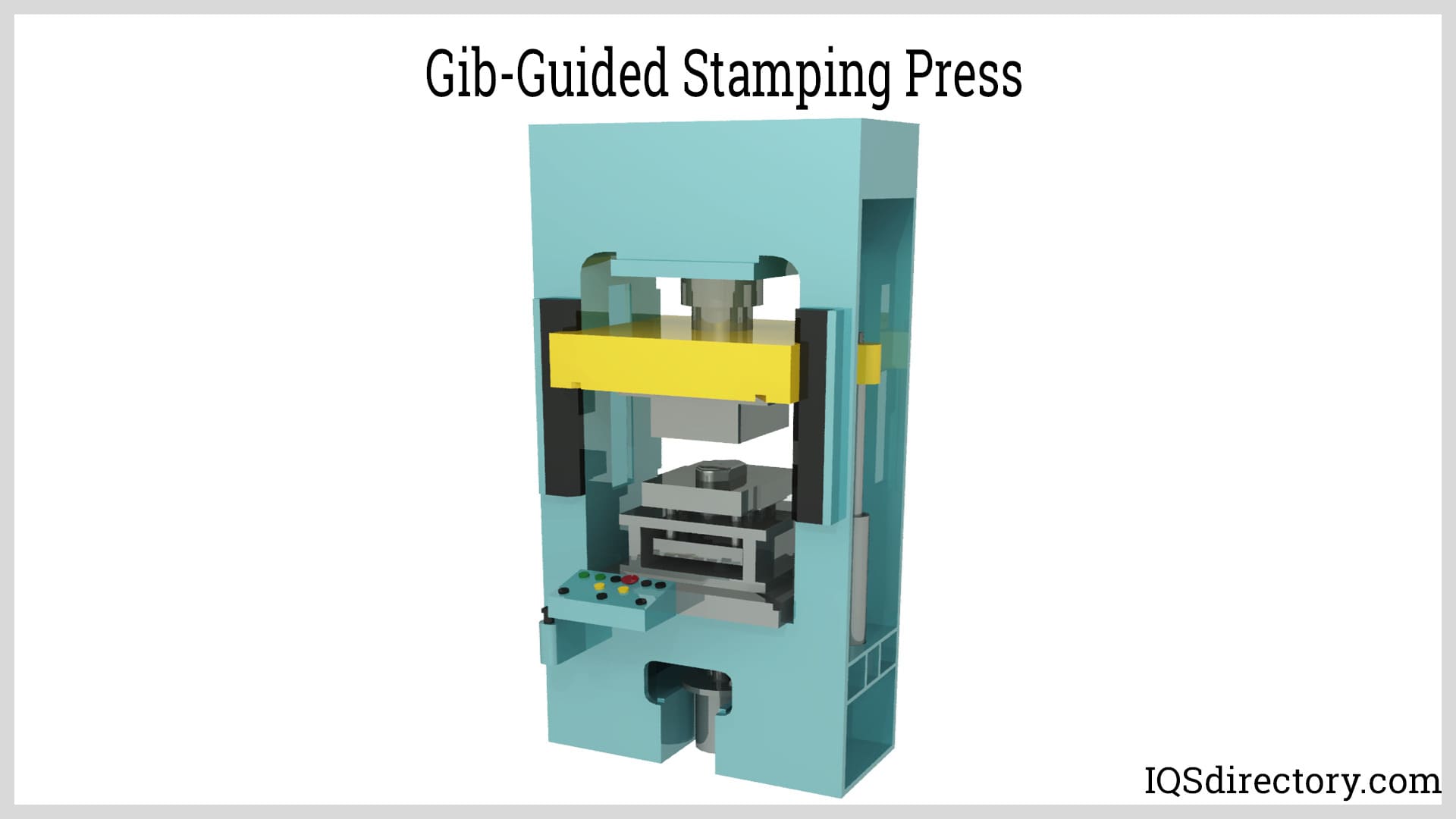

Gib-Guided Presses

Gib-guided stamping presses utilize rigid steel frames and precision gib guides to maintain ram and die alignment, even under severe off-center loading conditions. This robust construction makes gib-guided presses ideal for demanding stamping tasks, such as high-force blanking, progressive die work, and applications where tooling parallelism directly affects part quality and tool life.

Mechanical vs. Hydraulic vs. Servo Stamping Presses

- Mechanical Stamping Presses: Known for high-speed operation and efficiency in mass production. Best suited for blanking, piercing, and shallow forming where rapid stroke rates are required.

- Hydraulic Stamping Presses: Offer precise control of force and stroke, with adjustable speeds and built-in overload protection. Ideal for deep drawing, forming complex shapes, and operations requiring variable tonnage.

- Servo Stamping Presses: Feature programmable motion profiles, instant force delivery, and energy efficiency. Excellent for applications needing intricate forming, flexibility, and minimal tool wear.

Applications of Stamping Presses

Stamping presses are indispensable in a wide range of industries and manufacturing processes. Common applications include:

- Electronics Manufacturing: Precision stamping of connectors, terminals, and enclosures for circuit boards and electronic assemblies.

- Communication Devices: Fabrication of metal frames, shields, and housings for mobile phones, networking equipment, and telecom infrastructure.

- Computer Components: Production of chassis, brackets, heat sinks, and precision parts for desktops, laptops, and servers.

- Household Appliances: Stamping of panels, hinges, and structural elements for refrigerators, washing machines, ovens, and HVAC units.

- Furniture Manufacturing: Formation of brackets, supports, fasteners, and decorative trim for metal and hybrid furniture designs.

- Transportation: Large-scale stamping of body panels, frames, and structural parts for automobiles, motorcycles, bicycles, trucks, and rail vehicles.

- Industrial Hardware: Mass production of fasteners, fittings, gears, tools, and custom hardware for machinery and equipment.

- Aerospace & Defense: Precision forming of lightweight, high-strength components for aircraft, satellites, and military hardware.

- Medical Devices: Stamping of surgical instruments, device housings, and precision medical components from stainless steel and specialty alloys.

Wondering how stamping presses can improve your production line efficiency or help you achieve tighter tolerances in your products? Contact a stamping press supplier to discuss your unique manufacturing needs, or explore our directory of stamping press manufacturers for tailored solutions.

Benefits of Stamping Presses

Investing in a modern stamping press brings numerous operational and economic advantages to manufacturing operations:

1. Time Saving During Setup

Hydraulic stamping presses deliver full power at any point in the ram’s stroke, eliminating the need for precise location adjustments to achieve maximum tonnage. This feature significantly reduces setup times, allowing for faster changeovers between jobs and higher overall productivity.

2. Flexibility Across a Wide Application Range

Hydraulic and servo stamping presses can handle diverse forming tasks within their tonnage range, from high-volume production to complex part geometries. Their versatility extends to deep drawing, urethane bulging, piercing, straightening, staking, punching, assembly, powdered metal forming, bonding, abrasive wheel forming, broaching, ball sizing, rubber compression, and transfer molding. This adaptability makes them valuable assets for contract manufacturers and OEMs managing varied product lines.

3. Built-in Overload Protection

Hydraulic presses feature inherent overload protection: once the set pressure is reached, a relief valve activates to prevent overloading, tool damage, or press failure. This safety feature protects both equipment and personnel, reducing maintenance costs and minimizing unplanned downtime.

4. Lower Operating and Maintenance Costs

With fewer moving parts and a fully lubricated hydraulic system, stamping presses experience fewer breakdowns and require less maintenance than their mechanical counterparts. Parts such as solenoid coils, seals, and valves are affordable and easy to replace, further lowering the total cost of ownership.

5. Cost-Effectiveness for Larger Capacities

Hydraulic stamping presses are typically less expensive than equivalent-capacity mechanical presses. They are available in a wide range of standard and custom stroke lengths (e.g., 12, 18, 24 inches) and can be equipped with larger or smaller beds as needed. Their design flexibility and scalability make them a cost-effective choice for both large and small manufacturers.

6. Adjustable Operating Parameters

Operators can easily adjust ram force, speed, direction, pressure release, and dwell time to suit specific job requirements. This high level of control ensures consistent part quality, minimizes material waste, and allows for rapid adaptation to new product designs or changing customer demands.

7. Improved Part Quality and Repeatability

Advanced stamping presses, especially those with servo or precision hydraulic drives, deliver exceptional part-to-part consistency. Precise force, stroke, and speed control help maintain tight tolerances, reduce scrap, and ensure compliance with industry standards.

8. Enhanced Automation Integration

Modern stamping press systems can be seamlessly integrated with automation equipment, including robotic loaders, conveyors, automated die changers, and quality inspection stations. This integration supports lights-out manufacturing, improves throughput, and reduces labor costs.

How to Choose the Right Stamping Press for Your Application

When selecting a stamping press, it’s important to evaluate your production requirements and match them with suitable equipment features. Consider the following decision factors:

- Required Tonnage: Calculate the maximum force needed for your thickest material and largest part geometry.

- Bed Size and Stroke Length: Ensure the press accommodates your dies and workpieces, with room for future expansion.

- Type of Operation: Will you be performing blanking, piercing, deep drawing, progressive stamping, or a combination?

- Material Types: Evaluate compatibility with steel, aluminum, copper, brass, or specialty alloys.

- Production Volume: Higher volumes may favor mechanical or servo presses for speed, while lower volumes or complex parts may benefit from hydraulic models.

- Automation Needs: Consider integration with feeders, robots, and inspection systems to streamline workflow.

- Safety and Compliance: Look for presses that meet industry safety standards and include up-to-date guarding, light curtains, and emergency stops.

- Budget and Lifecycle Cost: Compare initial investment, maintenance, energy efficiency, and expected lifespan.

Need help selecting the best stamping press for your operation? Use our search prompts:

- Which stamping press is best for deep drawing automotive parts?

- What press tonnage do I need for stainless steel blanking?

- How do I automate tool changeovers on my stamping press?

- Where can I find high-speed servo stamping presses for electronics manufacturing?

- Who are the top-rated hydraulic press manufacturers in the US?

Choosing the Correct Stamping Press Supplier

Finding the right supplier is just as important as selecting the right machine. To ensure the best outcome when investing in a stamping press, compare multiple companies using our comprehensive directory of stamping press suppliers. Each supplier’s business profile page highlights their areas of expertise, manufacturing capabilities, support services, and industry certifications. Our directory enables you to:

- Quickly preview stamping press business websites using our proprietary website previewer

- Contact suppliers directly for product information, custom quotes, or technical support using integrated forms

- Submit RFQs to multiple stamping press companies with a single form for competitive pricing and faster decision-making

- Compare supplier lead times, warranty policies, and after-sales support

- Access case studies, customer reviews, and real-world success stories

Ready to take the next step? Browse our directory of stamping press manufacturers or request a quote now to discover the best solutions for your stamping, forming, and metal fabrication needs.

Frequently Asked Questions About Stamping Presses

- What is the difference between a hydraulic and a mechanical stamping press?

Hydraulic presses use liquid pressure for force, offer variable speed and force control, and are better for deep drawing and complex forming. Mechanical presses are faster, rely on flywheel energy, and are ideal for high-speed blanking and shallow forming. - How do I calculate the required tonnage for my stamping application?

Tonnage requirements depend on material type, thickness, part perimeter, and forming complexity. Many suppliers offer free tonnage calculators or engineering consultations. - Can stamping presses be used with non-metallic materials?

Yes, specialized stamping presses can form plastics, composites, rubber, and laminated materials, with appropriate dies and settings. - What safety features should I look for in a stamping press?

Key features include dual-hand controls, light curtains, emergency stops, interlocked guards, and compliance with OSHA or CE standards. - How do I maintain a stamping press for maximum uptime?

Regular lubrication, inspection of seals and guides, timely replacement of wear components, and adherence to manufacturer service schedules are essential.

Conclusion: Unlock Productivity and Precision with the Right Stamping Press

Stamping presses play a critical role in modern manufacturing, enabling the efficient production of high-quality, consistent parts across a multitude of industries. By understanding the types of presses available, their operating principles, component features, and application areas, buyers and engineers can make informed choices that boost productivity, cut costs, and enhance product quality.

For tailored recommendations, technical support, or to compare leading stamping press manufacturers, explore our directory or submit a request for quote today. The right stamping press investment can transform your production line and deliver a strong return on investment for years to come.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services