Press brakes are machines used in the bending of sheet metals. They are narrow and long so that any size of sheet metal can be easily bent. The traditional press brake machines are vertical, but the horizontal types are able to form long or narrow pieces of sheet metal that are usually difficult to bend. The press brake can bend a sheet metal several times until the required shape is reached. Read More…

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At Eagle Press & Equipment Co., we are dedicated to engineering and manufacturing high-quality hydraulic presses that meet the diverse needs of industries worldwide. With decades of expertise, we have built a reputation for delivering presses that offer superior performance, reliability, and precision, supporting everything from small-scale production to heavy-duty manufacturing applications.

At AIDA-America Corp., we are dedicated to advancing the manufacturing industry through our expertise in hydraulic press technology. We design and build presses that deliver precision, efficiency, and reliability for high-volume production environments.

At Hydraulico Inc., we have built our reputation as a leader in hydraulic press engineering by combining decades of expertise with a passion for innovation and precision. We design and manufacture high-performance hydraulic presses that meet the demands of industries ranging from automotive and aerospace to metal forming, appliance production, and advanced material processing.

More Press Brake Manufacturers

Hydraulic Press Brakes: Comprehensive Guide, Applications, and Buying Considerations

Hydraulic press brakes are essential pieces of equipment in modern metal fabrication, sheet metal processing, and manufacturing industries. These machines are designed to accurately bend, fold, and shape sheet metal by lowering a punch into the material, which is positioned atop a die. While there are several types of press brakes—including mechanical, hydraulic, and electric—this guide will focus on the hydraulic press brake, recognized for its power, efficiency, and precision across a wide range of sheet metal forming applications.

What is a Hydraulic Press Brake?

A hydraulic press brake is a machine tool that uses hydraulic pressure to force a ram downward onto a workpiece, deforming the material to a precise angle or shape. Unlike mechanical or electric press brakes, which use flywheels or electric motors to generate force, hydraulic press brakes rely on the controlled movement and pressure of hydraulic fluid. This results in smoother operation, superior control, and the ability to apply consistent force throughout the bending process.

Modern hydraulic press brakes are often equipped with multiple hydraulic cylinders. This multi-cylinder configuration gives operators precise control over the bending process, allowing for customized bends with tight tolerances. Advanced hydraulic press brake models may also include CNC (computer numerical control) systems for automated operations, programmable back gauges, and safety features to enhance both productivity and operator protection.

How Does a Hydraulic Press Brake Work?

The working principle of a hydraulic press brake is rooted in Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. Here’s how the process unfolds:

- The machine’s hydraulic system consists of two main pistons—one smaller (the pump piston) and one larger (the press cylinder piston).

- A relatively small mechanical force is applied to the small piston, creating hydraulic pressure within the closed system.

- This pressure is transmitted through hydraulic fluid to the larger piston, which multiplies the force and drives the ram downward with significant force onto the workpiece.

- The ram presses the punch into the sheet metal, which is positioned over the die, creating the desired bend or shape.

This hydraulic power transmission enables the press brake to handle thick metals and high-tensile materials with ease, making it indispensable for heavy-duty metal forming applications.

Types of Press Brakes

Press brakes can be categorized based on their operating mechanism and motion. Understanding the differences helps buyers select the right press brake for their specific fabrication requirements.

1. Down-Acting Press Brake

The down-acting press brake is the most common type used in metal fabrication shops. In this configuration, the upper beam (ram) moves downward toward a fixed bed holding the bottom die. Driven by two or more hydraulic cylinders, down-acting press brakes offer:

- Excellent bending accuracy

- Consistent force application

- Ease of use for operators

These machines are ideal for high-production environments where repeatability and precision are crucial.

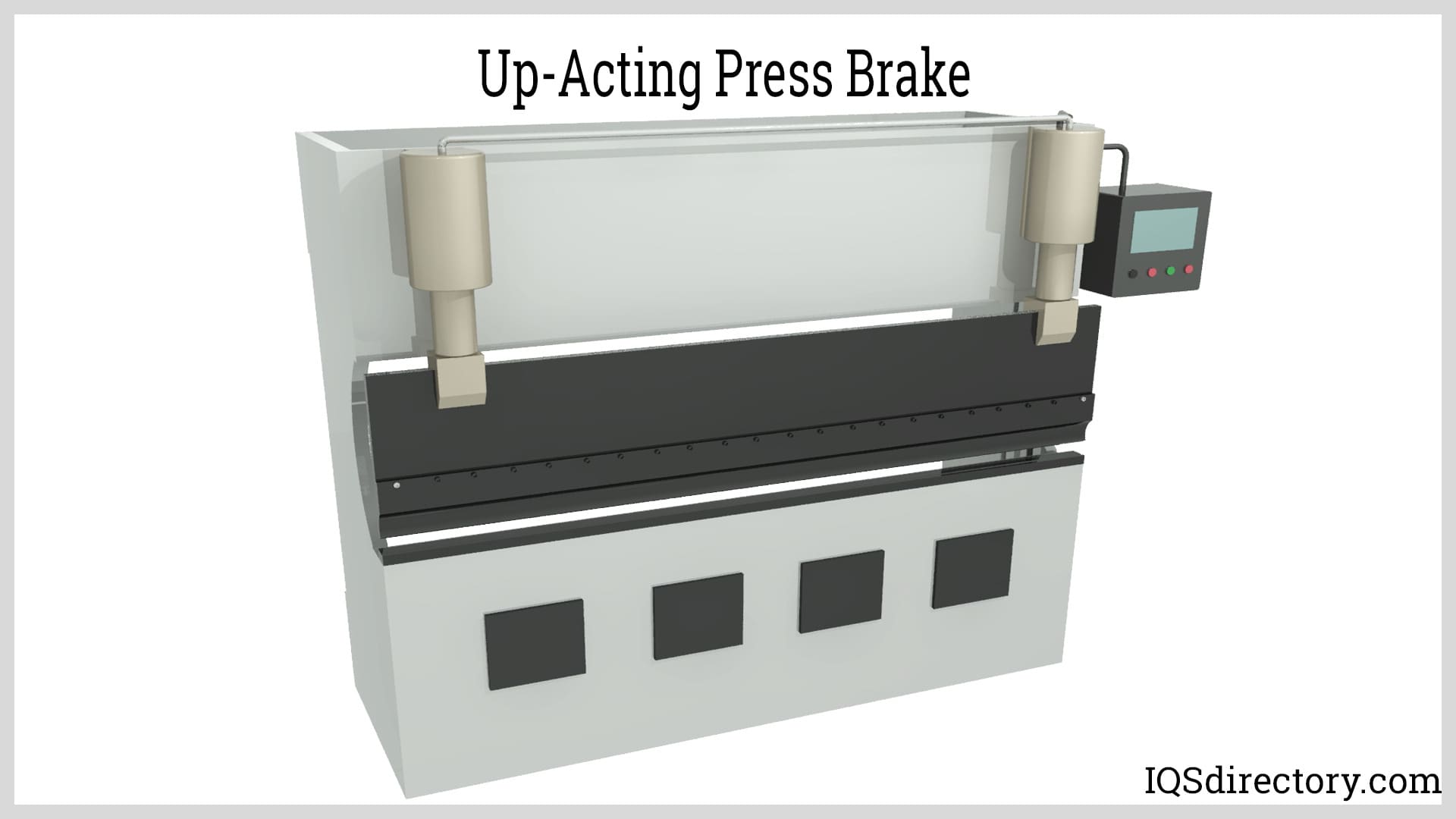

2. Up-Acting Press Brake

An up-acting press brake operates in the opposite manner: the lower beam carrying the die moves upward toward a stationary ram holding the punch. This motion allows for:

- Low mounting of hydraulic components

- Enhanced safety in some applications

- Improved access for part removal and setup

However, the operator must hold the workpiece in place throughout the entire bending cycle, which can impact efficiency for certain jobs.

3. Other Press Brake Types

While hydraulic press brakes dominate the industry, it’s helpful to understand other available types for comparison:

- Mechanical Press Brakes: Use flywheels and mechanical linkages for force generation. They offer high speed but less control and safety compared to hydraulic models.

- Servo-Electric Press Brakes: Rely on electric motors and ball screws for force delivery. These machines are energy-efficient and provide high precision, often used for lighter gauge materials and small batch production.

- Hybrid Press Brakes: Combine hydraulic and electric technologies for improved energy efficiency, faster cycle times, and advanced automation features.

Key Applications of Hydraulic Press Brakes

Hydraulic press brakes are indispensable in a wide range of industries due to their versatility, power, and precision. Typical applications include:

- Molding and Metal Forming: Creating complex bends, curves, and shapes in sheet metal parts for various industrial uses.

- Blanking and Punching: Cutting and forming processes for metal sheets, particularly in automotive and appliance manufacturing.

- Deep Drawing: Forming metal sheets into deep, hollow shapes for containers, enclosures, and structural components.

- Clinching and Fastening: Joining sheet metals without the need for welding or additional fasteners.

- Forging: Applying controlled force to shape metal parts, such as those found in aerospace and marine engineering.

Industries that rely heavily on hydraulic press brakes include:

- Automotive manufacturing

- Aerospace and aviation

- Shipbuilding and marine engineering

- Furniture production

- HVAC and appliance manufacturing

- General metalworking and fabrication shops

- Construction and infrastructure

- Electrical enclosures and metal containers

- Renewable energy equipment manufacturing

- Railway and transportation equipment

Looking for industry-specific applications or case studies? Explore how hydraulic press brakes are used in your sector:

- How are press brakes used in automotive manufacturing?

- Press brake solutions for aerospace and defense

- What role do press brakes play in metal fabrication?

Advantages and Benefits of Hydraulic Press Brakes

Why do metal fabricators, OEMs, and job shops prefer hydraulic press brakes over other forming equipment? Here are the primary benefits that drive their popularity:

1. Cost-Effectiveness and Low Maintenance

Hydraulic press brakes are generally more affordable than mechanical alternatives, especially when considering maintenance and replacement costs. With fewer moving parts and readily available components, downtime is minimized, and repair expenses are lower. The pressure can be precisely set for each job, reducing tool wear and prolonging tooling life.

2. Built-In Overload Protection

Hydraulic systems include overload protection via relief valves, ensuring the press never exceeds its rated tonnage. This prevents accidental overloading, reduces the risk of machine or tool damage, and safeguards operators.

3. Superior Precision and Repeatability

Modern hydraulic press brakes, especially those with CNC controls, offer exceptional precision. Operators can program exact bend angles, back gauge positions, and ram speeds, ensuring consistency across high-volume production runs.

4. Quiet Operation

Compared to mechanical press brakes, hydraulic models operate more quietly. Fewer moving parts and controlled ram movement result in reduced noise levels, enhancing operator comfort and meeting workplace safety regulations.

5. Space-Saving Design

Hydraulic press brakes deliver high force in a compact footprint. This makes them ideal for shops with limited floor space, enabling manufacturers to maximize their production area without sacrificing performance.

6. Flexible Control and Versatility

Operators can adjust ram force, speed, and return position to accommodate a variety of bending operations. This flexibility allows manufacturers to work with different materials, thicknesses, and bend profiles using a single machine. Common operations include:

- Bending and folding

- Coining and bottoming

- Air bending

- Embossing

- Hemming

- Deep drawing and forming

- Transfer molding

- Straightening and flattening

- Press fits and bonding

7. Energy Efficiency and Eco-Friendliness

Modern hydraulic press brakes are designed with energy-saving features such as variable-speed pumps and automatic shut-off controls. This reduces power consumption, lowers operating costs, and supports sustainability initiatives.

8. Enhanced Safety Features

Hydraulic press brakes often integrate advanced safety systems, including light curtains, interlock guards, and emergency stop mechanisms. These features help prevent workplace accidents and ensure compliance with OSHA and international safety standards.

How to Choose the Right Hydraulic Press Brake

With various press brake models, tonnages, and features available, making the right purchase decision requires careful consideration of several factors. Use these key questions and decision points to guide your selection process:

1. What is the Maximum Material Thickness and Type?

Identify the thickest and hardest materials you plan to bend, as this determines the required press brake tonnage. Consider the yield strength of materials such as mild steel, stainless steel, aluminum, or high-strength alloys.

2. What are Your Typical Bend Lengths and Profiles?

Choose a machine with a bed length and open height sufficient for your longest and most complex parts. Will you need to form large panels or intricate, multi-bend components?

3. Manual, NC, or CNC Controls?

Manual press brakes are suitable for simple, low-volume jobs. For repetitive, complex, or high-volume production, a CNC hydraulic press brake offers automated programming, higher accuracy, and reduced setup times.

4. What About Tooling Compatibility?

Ensure the press brake is compatible with your existing dies, punches, and clamping systems. Consider quick-change tooling and modular systems to improve setup efficiency.

5. What Tonnage and Stroke Length Do You Need?

Calculate the required tonnage based on material type, thickness, and bend length. Make sure the machine has adequate stroke length and daylight opening for your applications.

6. Does the Manufacturer Offer Support and Service?

Partner with a reputable press brake manufacturer or supplier that provides training, technical support, spare parts, and after-sales service. Quick response times can minimize downtime and maximize productivity.

7. What Automation Features Are Available?

Consider advanced features such as programmable back gauges, automatic crowning, bend angle measurement systems, and robotic integration for lights-out manufacturing.

Start your search for the right hydraulic press brake by browsing our press brake manufacturer directory. Compare specifications, request quotes, and review customer testimonials before making a final decision.

Frequently Asked Questions about Hydraulic Press Brakes

What maintenance is required for hydraulic press brakes?

Regular maintenance includes checking hydraulic fluid levels, inspecting seals and hoses for leaks, cleaning filters, lubricating moving parts, and calibrating CNC controls. Preventive maintenance schedules extend machine life and prevent costly breakdowns.

How do I calculate the required tonnage for my job?

Tonnage depends on material type, thickness, and bend length. Use manufacturer-supplied tonnage charts or online calculators. When in doubt, consult your supplier for recommendations.

Are hydraulic press brakes suitable for prototype and custom jobs?

Yes, hydraulic press brakes offer excellent flexibility for custom and one-off production runs. Programmable controls and adjustable settings make them ideal for prototyping and short runs.

How do I improve bend accuracy and reduce waste?

Invest in CNC-controlled press brakes, use high-quality tooling, and perform regular machine calibration. Operator training and process monitoring also contribute to higher accuracy and reduced scrap rates.

Can hydraulic press brakes be integrated with other automation equipment?

Absolutely. Many modern hydraulic press brakes can be networked with robotic loaders/unloaders, material handling systems, and ERP software for smart factory integration and Industry 4.0 readiness.

Current Trends and Innovations in Hydraulic Press Brakes

The press brake market continues to evolve, with new technologies and innovations shaping the future of metal fabrication. Key trends include:

- Industry 4.0 and Smart Manufacturing: Integration of IoT sensors, cloud connectivity, and real-time data analytics for predictive maintenance and process optimization.

- Energy-Efficient Hydraulics: Variable speed pumps and eco-efficient drive systems reduce power consumption and environmental impact.

- Advanced Safety and Ergonomics: Enhanced guarding, laser safety systems, and ergonomic controls protect operators and reduce fatigue.

- Automated Tooling Changes: Quick-change dies and automatic clamping systems minimize setup times and increase throughput.

- Increased Customization: Manufacturers can now specify custom machine sizes, features, and automation options to fit their unique production needs.

Curious about the latest advancements? Explore new technology trends in hydraulic press brakes.

Conclusion: Invest in the Right Hydraulic Press Brake for Your Business

Hydraulic press brakes stand as the backbone of modern sheet metal fabrication, offering unmatched versatility, precision, and efficiency. Whether you operate a small job shop or a large-scale production facility, investing in the right press brake can significantly improve your productivity, reduce costs, and expand your manufacturing capabilities.

Ready to take the next step? Use our press brake manufacturer directory to compare leading suppliers, read in-depth company profiles, and request custom quotes. Not sure what you need? Contact our hydraulic press experts for personalized advice and recommendations tailored to your application.

Looking to learn more? Try searching:

- What are the differences between hydraulic, mechanical, and electric press brakes?

- How do I calculate press brake tonnage for stainless steel?

- What safety standards apply to hydraulic press brakes?

- Best practices for maintaining hydraulic press brakes

For more information on hydraulic presses, metal forming equipment, and fabrication solutions, visit our hydraulic press resource center.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services