Using a power press machine, any metal sheet can be cut, shaped, blended, and pressed into the desired shape. Die sets for power presses are affixed to the slide and bed. The slide moves in a controlled reciprocating manner both parallel to and perpendicular to the bed surface. This machine serves various functions, including shaping metal sheets into the proper shape for parts used in automobiles, electric and electronic appliances, and other applications. In addition, it is used in a range of heavy industrial applications, including metal fabrication, and is one of the most flexible sheet metal machines on the market. Read More…

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At Custom Engineering Company, we specialize in the design and manufacture of hydraulic presses that deliver precision, power, and durability. With decades of expertise, we provide custom-engineered solutions that meet the unique demands of various industries. Our hydraulic presses are known for their robust construction, high efficiency, and reliability, ensuring optimal performance in even the...

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Power Press Manufacturers

How Power Presses Function

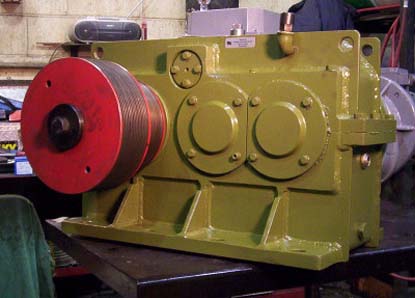

The main parts of a power press are the clutch, flywheel, crankshaft, static ram, and moving ram. The ram reciprocates back and forth inside its guideways, dictating the length and force of each stroke. The stroke length and power imparted can be changed according to the needs. A punch is carried by the ram's bottom end to process the workpiece.

The driving shaft's edge is where the flywheel is located, and a clutch connects it to the shaft. The flywheel stores the energy during periods of inactivity, and it is anticipated that it will maintain the constant speed of the ram when the punch is depressed into the work. When the ram has to start or stop moving, the clutch connects and disengages the driving shaft from the flywheel.

The power press machine's design concept is to change circular motion into linear motion. A clutch connects the crankshaft to the rotating flywheel. The press ram's upward and downward motions are coupled with the flywheel's rotation via the crankshaft. The tool cycle is started after a workpiece is fed into the die. A re-formed piece is produced when the stock material is compressed between the top and lower dies. After the downstroke is complete, the formed workspace is removed, and a new plate form is used to perform the same procedure.

Types of Power Presses

Pneumatic Press Machine

A pneumatic press manipulates a workpiece using a pneumatic system. The top of the pneumatic press lowers to manipulate the workpiece using high pressure once it has been set in the center of the frame. Pneumatic presses are fast, incredibly flexible, and simple to operate. They are typically employed in low-tonnage operations and small-scale production; for instance, they are frequently utilized in workshops and laboratories. Marking, swaging, and riveting are particularly well-suited to pneumatic presses. In general, they are less expensive than hydraulic presses.

Hydraulic Press

A machine press known as a hydraulic press produces compressive force using a hydraulic cylinder. It makes use of a hydraulic version of a mechanical lever. The hydraulic press is based on Pascal's law, which states that pressure in a closed system remains constant. The system consists of two pistons: one serves as a pump and exerts a tiny amount of mechanical force on a small cross-sectional area. At the same time, the other has a greater area and produces a much bigger mechanical force. If the pump is removed from the press cylinder, all required for tubing is small-diameter tubing that can more easily withstand pressure.

Mechanical Power Press

A mechanical power press, also known as a mechanical press, is a device based on a slider-crank mechanism that transforms rotating motion into reciprocating motion, transferring force or energy to sheet metal. Sheet metal deforms plastically when this energy is transferred, giving the metal the desired shape. The mechanical press's operating principle converts the electric motor's rotational power into a translational power that powers the pressing mechanism.

C Frame Power Press

The frame is used for compact presses up to 250 tons and has a C shape. However, press frames have a limitation when high accuracy and mass manufacturing are required because of the C shape's higher longitudinal and angular deflection than other frame types. Therefore, with presses up to 100 tons, C frame presses are increasingly prevalent.

Single Piece H Frame Type

This H-shaped box-type design delivers greater rigidity, zero deflection, and long-lasting smooth and accurate task performance. This frame can only be used in front of the press and has four box-like pillars. The open windows determine job size. An H-frame design will increase tool life and job operation precision. However, it costs more than the ring frame press and C-frame power press. An H frame is stiff, but because it is made of a single component, handling the press on the shop floor becomes challenging for higher tonnage capacities exceeding 400 tons because the frame would grow too large. Therefore, this press is used for up to 400 tons.

Benefits of Power Press Machines

- Previously, pressing and shaping had to be done by hand. This machine has allowed for significant labor and effort savings.

- A power press eliminates the requirement for repetitive machine assembly of the work parts.

- Power presses perform various tasks, including cutting, pressing, trimming, and straightening.

- Compared to manual labor, using a power press machine is considerably simpler to operate, and its portability and design allow it to move around the workshop easily.

- This equipment is easy to operate and has a cheap initial cost.

Choosing the Correct Power Press Supplier

To ensure you have the most productive outcome when purchasing a power press from a power press supplier, it is important to compare several companies using our directory of power press suppliers. Each power press supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each power press business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple power press companies with the same form.

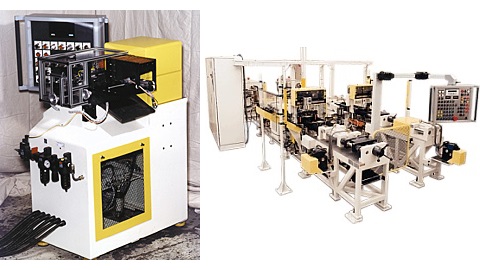

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services