Macrodyne Hydraulic Presses & Automation

Macrodyne Hydraulic Presses & AutomationRequest A Quote

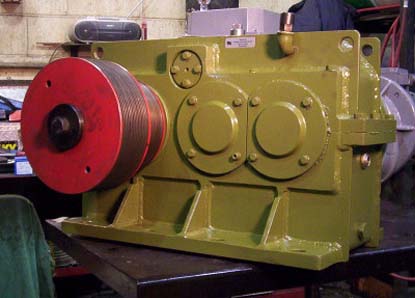

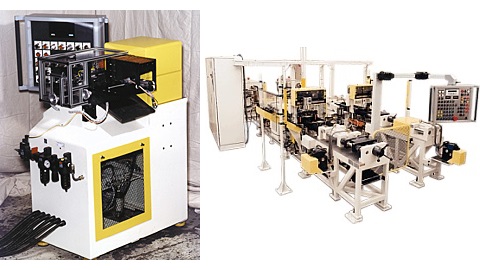

Concord, ONMacrodyne Hydraulic Presses & Automation is the industry leader in quality, innovation, and value. Located in Concord, Ontario, our company is a major manufacturer and supplier of power presses, hydraulic presses, press lines, and die handling equipment. Our dedicated team of engineers welcomes the opportunity to assist our customers in any way they can, and value is our first priority. We take a lean approach to manufacturing to ensure that customers are receiving the highest quality products at competitive prices. With decades of experience, our press designs have continued to improve in versatility and flexibility. Press systems are built for applications requiring between 50 and 10,000 tons and can be used with many different materials, such as plastic, rubber, metal, and wood. We understand the demands of modern manufacturing, so up-time, serviceability, and reliability are all extremely important factors in the process of designing and manufacturing these press systems. We utilize mechanical, hydraulic, and electrical design groups to guarantee that every aspect of our presses is maximizing value and meeting customers’ expectations. Dedication to innovation has pushed us to continually design and develop new and useful features for our press systems. Several frame options are offered, including C-frames, straight side frames, and monolithic frames, to serve almost any hydraulic press application. The very latest state-of-the-art hydraulic components are incorporated to maximize efficiency and improve reliability, and customers can choose from many press and control features to enhance their hydraulic systems. We also design press control systems from basic manual controls to complex computer based systems to meet any budget or application need.

Leading Hydraulic Press Manufacturers

More Hydraulic Press Manufacturers

Additional Categories: Cooling Towers, Copper Brass Bronze, Power Cords

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services