Heavy-duty presses such as these are ideal for testing materials such as rubber, plastic, wood and ceramics. With this type of press, it is possible to adjust the amount of exerted pressure as well as the number of samples produced. Read More…

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At Eagle Press & Equipment Co., we are dedicated to engineering and manufacturing high-quality hydraulic presses that meet the diverse needs of industries worldwide. With decades of expertise, we have built a reputation for delivering presses that offer superior performance, reliability, and precision, supporting everything from small-scale production to heavy-duty manufacturing applications.

At AIDA-America Corp., we are dedicated to advancing the manufacturing industry through our expertise in hydraulic press technology. We design and build presses that deliver precision, efficiency, and reliability for high-volume production environments.

At Hydraulico Inc., we have built our reputation as a leader in hydraulic press engineering by combining decades of expertise with a passion for innovation and precision. We design and manufacture high-performance hydraulic presses that meet the demands of industries ranging from automotive and aerospace to metal forming, appliance production, and advanced material processing.

More Laboratory Press Manufacturers

Companies that manufacture these presses usually offer a handful of options with various ranges of temperature, pressure and platen sizes along with customization in order to meet particular processes. Most laboratory press manufacturers design them with low maintenance requirements, low noise levels and with a minimum use of space.

Pharmaceutical, laminating and rubber and plastic molding industries are among those that benefit from laboratory presses. Laboratory presses are also common among R&D work, testing, short runs, limited production, cell manufacturing and lean manufacturing.

The main reason that scientists and researchers prefer these types of presses is because of their undeniable precision and their ability to meet rigorous demands. The durability of lab presses also ensures long life in the lab, providing long-lasting and consistent results.

Operations within research come with high demands, which is exactly why laboratory presses are an integral part in industrial inquiries. For testing and compacting materials such as rubber, plastic and laminate materials, these heavy-duty machines are extremely important.

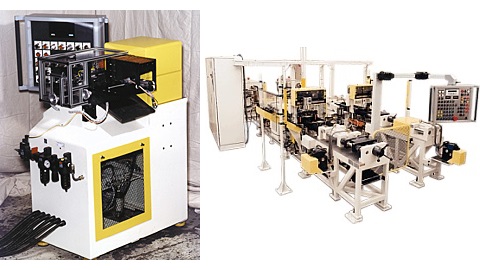

The design and manufacture of these presses typically includes programmable controls, allowing users to press products more accurately, consistently and according to specific requirements. Though many lab presses are fit for the countertop, there are also many floor standing presses available. Either way, it is not uncommon to find laboratory presses designed with two-columns and four-columns and that press either manually or automatically.

With such a vast selection of laboratory presses out in the market, it could become confusing as to which one is best suited for a particular job. An important factor to remember when choosing this particular kind of hydraulic press is how much force is needed for a specific sample?

It is also necessary to consider how much space is provided in the lab, how much energy and strength is required to pump the press and whether or not the press will have to move.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services