Transfer presses combine the best features of compression molding with all the advantages of injection molding. A transfer press, like a plastic injection molding machine, has the capability to produce plastics with high productivity. In addition, a transfer press is an automated multi-stage press characterized by a high degree of automation. Read More…

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At AIDA-America Corp., we are dedicated to advancing the manufacturing industry through our expertise in hydraulic press technology. We design and build presses that deliver precision, efficiency, and reliability for high-volume production environments.

At Eagle Press & Equipment Co., we are dedicated to engineering and manufacturing high-quality hydraulic presses that meet the diverse needs of industries worldwide. With decades of expertise, we have built a reputation for delivering presses that offer superior performance, reliability, and precision, supporting everything from small-scale production to heavy-duty manufacturing applications.

At Hydraulico Inc., we have built our reputation as a leader in hydraulic press engineering by combining decades of expertise with a passion for innovation and precision. We design and manufacture high-performance hydraulic presses that meet the demands of industries ranging from automotive and aerospace to metal forming, appliance production, and advanced material processing.

More Transfer Press Manufacturers

Transfer Presses: Industrial Solutions for Efficient Stamping and Fabrication

In today’s competitive manufacturing sector, transfer presses are indispensable for businesses seeking automation, precision, and cost-effective large-scale production. Whether you’re in automotive, aerospace, appliance, or general metal fabrication, a quality transfer press streamlines your workflow, drives productivity, and delivers consistent product quality. This comprehensive guide delves into the mechanics, types, applications, selection criteria, and industry-specific benefits of transfer presses, helping you make informed decisions for your next equipment investment.

What is a Transfer Press?

A transfer press is a specialized machine used primarily in industrial stamping and forming processes, where parts are automatically moved between different workstations or dies. These presses are crucial for producing complex or large components with multiple forming, cutting, or assembly steps. In textile finishing, transfer presses are utilized for applying flex films, flock foils, screen printing transfers, toner transfers, and other transfer media onto textiles and garments. Their versatility and adaptability make them a top choice for manufacturers looking to reduce cycle times and lower tooling costs while maintaining high throughput and product quality.

How Does a Transfer Press Work?

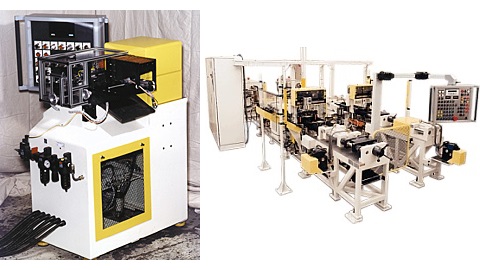

A transfer press automates the transfer of a workpiece from one station to another using hydraulic, mechanical, or servo-driven transport systems. Unlike progressive die presses, where the workpiece remains attached to a metal strip throughout the process, transfer presses separate each blank early, allowing for more complex shapes and operations. This transfer die stamping process is ideal for parts that require operations not possible while attached to a strip, such as deep drawing, flanging, piercing, or tapping from different angles.

Typically, the process begins with coil or blank material fed into the first station via a coil processing line, parts loader, or blank loader. The blank is then separated from the strip and transferred by programmable fingers or grippers through a series of transfer dies, each performing a specific operation. Upon completion, the finished parts are discharged by a conveyor system, ready for secondary processing or assembly.

Transfer Press vs. Progressive Die Press: Key Differences

Both transfer presses and progressive die presses are essential in modern stamping operations, but each serves distinct purposes and offers unique advantages:

- Transfer Press: Each blank is separated early and moved independently, allowing unrestricted access and complex operations on each part. Ideal for large, intricate, or deep-drawn components.

- Progressive Die Press: The workpiece remains attached to the strip throughout most operations, limiting the types of forming but enabling extremely high-speed production for simpler parts.

Types of Transfer Presses

Understanding the different types of transfer presses is crucial for selecting the right equipment for your application. The two main types include:

Individual Cam Operated Plungers

In these presses, each workstation is powered by its own cam-operated plunger, enabling independent yet synchronized motion across stations. This design allows for easy adjustment and customization of each forming or stamping operation, making it ideal for short production runs or when frequent reconfiguration is necessary. Cam-operated transfer presses are valued for their flexibility and precision in handling complex part geometries.

Solid Bed Die Set Press

This variant uses a flat, solid bed to coordinate the press action across multiple stations, activating them simultaneously. Without relying on a rotary mechanism, solid bed presses offer robust performance and are well-suited for high-volume, repeatable operations. The solid bed design ensures even force distribution and stable die alignment across all stations, reducing maintenance and downtime.

Servo-Driven Transfer Presses

Modern manufacturing increasingly relies on servo-driven transfer presses for advanced motion control and energy efficiency. Servo motors provide programmable, precise motion profiles, enabling rapid die changes, optimized stroke lengths, and reduced power consumption. These presses are ideal for manufacturers demanding both speed and adaptability in their stamping lines.

Hydraulic Transfer Presses

Hydraulic transfer presses use hydraulic cylinders and advanced valve systems (such as Schuler’s ring valve technology) to deliver powerful, consistent force for heavy-duty forming operations. They excel in applications requiring deep drawing and high tonnage, making them a mainstay in automotive body panel production, appliance housings, and large structural components.

Transfer Press Applications Across Industries

Transfer presses are versatile machines deployed across a range of industries and applications, including:

- Automotive Manufacturing: Stamping of body panels, frames, brackets, and structural parts requiring complex geometry or large dimensions.

- Aerospace & Defense: Fabrication of precision components, enclosures, and assemblies demanding tight tolerances and robust performance.

- Appliance Production: Forming of outer shells, doors, and functional parts for washers, dryers, ovens, and refrigerators.

- Electronics & Electrical Enclosures: Stamping of chassis, heat sinks, and custom enclosures with intricate features.

- Metal Furniture & Architectural Components: Production of support frames, rails, panels, and decorative elements.

- Textile Finishing: Application of flex films, flock foils, and screen printing transfers onto garment fabrics and accessories.

- Heavy Equipment & Industrial Machinery: Creation of large, heavy-gauge parts for construction and agricultural machinery.

- General Metal Fabrication: Manufacturing of custom parts, prototypes, and assemblies where flexibility and fast changeover are required.

Common Use Cases and Product Examples

- Frames and structural components for vehicles and equipment

- Shells and tubes for pressure vessels and piping systems

- Complex brackets, supports, and custom hardware

- Stamped electrical contacts and connectors

- Decorative and functional panels for appliances and consumer goods

- High-precision components for aerospace assemblies

- Garment embellishments and textile branding elements

Benefits of Using Transfer Presses in Manufacturing

Investing in a transfer press can transform your production capabilities and impact your bottom line. Here’s how:

- Design Versatility: Multiple operations—such as chamfering, piercing, ribbing, cut-outs, threading, and knurling—can be performed in a single setup, eliminating secondary processes and reducing time to market.

- Setup Flexibility: Transfer presses support single or multiple dies, and can be arranged in standalone or inline production cells to fit diverse project requirements.

- Increased Productivity: Automated part transfer and simultaneous multi-die operation enable high-volume, continuous production with minimal manual intervention.

- Precision and Consistency: Programmable motion and advanced alignment systems ensure every part meets tight tolerances, reducing scrap and rework rates.

- Reduced Tooling Costs: Fewer dies and less complex tooling are required compared to progressive die systems, especially for low- to medium-volume runs with complex geometries.

- Fast Die Changes: Modern presses feature rapid die change systems, minimizing downtime and supporting just-in-time manufacturing approaches.

- Reliability and Uptime: Engineered for robust, continuous operation, transfer presses deliver long-term reliability and minimal maintenance requirements.

- Automatic Process Control: Integrated sensors, PLCs, and automation platforms ensure real-time monitoring, error detection, and process optimization.

How to Choose the Right Transfer Press for Your Operation

Selecting the optimal transfer press involves careful consideration of your production needs, material types, part complexity, and future scalability. Start by evaluating the following:

- Production Volume: High-volume, repeatable runs benefit from solid bed or servo-driven presses, while custom or low-volume jobs may require more flexible cam-operated systems.

- Material Type & Thickness: Ensure your press can accommodate the gauge, strength, and ductility of materials you process most frequently—be it steel, stainless steel, aluminum, copper, or specialty alloys.

- Part Size & Complexity: Large or intricate parts may require presses with larger bed sizes, higher tonnage, and advanced transfer systems.

- Automation & Integration: Decide if you need integration with coil feed lines, robots, conveyors, or other automation for seamless, lights-out operation.

- Budget & Total Cost of Ownership: Factor in not only initial purchase price, but also maintenance, tooling, energy consumption, and potential productivity gains.

- Manufacturer Support: Select a supplier with proven experience, strong technical support, and readily available spare parts and service.

Are you comparing transfer press models or trying to decide which stamping press best fits your production goals? Explore our transfer press manufacturer directory below to request quotes, download product specifications, or connect with application engineers for tailored recommendations.

Key Features to Consider When Buying a Transfer Press

When evaluating transfer presses for purchase or upgrade, look for these critical features:

- Press Tonnage: Match the press force to your most demanding forming operations and material strengths.

- Bed Size & Stroke Length: Ensure adequate working area and stroke for your largest parts and deepest draws.

- Transfer System: Choose between hydraulic, mechanical, or servo-driven designs based on required speed, flexibility, and precision.

- Die Change Mechanisms: Quick-change tooling systems reduce downtime and support high-mix, low-volume manufacturing.

- Automation Readiness: Compatibility with robots, conveyors, and part handling equipment streamlines overall workflow.

- Control Systems: Modern PLCs, HMI touchscreens, and remote diagnostics for real-time monitoring and process optimization.

- Safety Features: Integrated light curtains, guarding, and emergency stop systems protect operators and ensure regulatory compliance.

Not sure what features matter most for your application? Ask us: What size and tonnage transfer press do I need for automotive body panel stamping? or How can I automate die changes in my stamping line?

Transfer Presses vs. Other Stamping Technologies

When evaluating stamping equipment, manufacturers often compare transfer presses with other popular systems:

- Transfer Presses vs. Progressive Die Presses: Transfer presses excel at complex, multi-operation parts and deep draws, while progressive dies are ideal for simple, high-speed, low-cost stamping.

- Transfer Presses vs. Tandem Press Lines: Tandem lines use multiple presses in sequence; transfer presses consolidate multiple operations into one or a few presses, reducing floor space and handling time.

- Transfer Presses vs. Hydraulic Presses: Though many transfer presses use hydraulic power, standalone hydraulic presses are typically used for single, high-force forming or deep drawing operations without automatic transfer mechanisms.

Curious about which press type best fits your business? Compare stamping press technologies here or request a custom equipment assessment.

Transfer Press Maintenance and Best Practices

Maximize uptime and equipment lifespan by following these maintenance and operational best practices:

- Schedule regular inspections of transfer mechanisms, dies, and hydraulic or servo systems.

- Monitor lubrication levels and apply recommended greases and oils to moving parts.

- Keep dies sharp and aligned to prevent misfeeds and part defects.

- Utilize integrated diagnostics and predictive maintenance tools where available.

- Train operators on safety protocols and troubleshooting common alarms or stoppages.

- Document all maintenance and repairs for warranty and compliance purposes.

Looking for a detailed maintenance checklist or troubleshooting guide? Access transfer press maintenance resources.

Choosing the Proper Transfer Press Manufacturer

To ensure a successful investment in a new or used transfer press, compare several manufacturers using our comprehensive transfer press manufacturer directory. Each profile highlights the company’s areas of expertise, industry certifications, and stamped parts portfolio. You can:

- View a patented website previewer to rapidly evaluate each supplier’s capabilities and specializations.

- Use a simple RFQ (request for quote) form to contact multiple transfer press manufacturers simultaneously and compare competitive offers.

- Request references, sample parts, or case studies to verify quality and reliability.

- Engage directly with technical sales, application engineers, or customer support for tailored guidance.

Ready to take the next step? Request transfer press quotes or schedule a demo with top-rated suppliers in our directory.

Frequently Asked Questions About Transfer Presses

- What is the difference between a transfer press and a progressive die press?

A transfer press separates each blank from the strip early and moves it independently through multiple operations, allowing more complex forming. Progressive die presses keep the workpiece attached to the strip until the final step, limiting complexity but enabling higher speeds for simple parts. - What are the main advantages of using a transfer press?

Transfer presses offer greater flexibility, support complex part geometries, reduce secondary operations, and enable rapid changeover, making them ideal for automotive, appliance, aerospace, and custom fabrication markets. - How do I calculate the required tonnage for my transfer press?

Calculate the required tonnage by multiplying the material thickness, shear strength, and part perimeter, then add a safety margin. Consult your press manufacturer for application-specific recommendations. - Can transfer presses be integrated with robotic automation?

Yes, modern transfer presses are designed for seamless integration with robots, conveyors, and vision systems for fully automated, lights-out manufacturing. - What materials can be processed using transfer presses?

Transfer presses can handle a wide range of materials, including mild steel, stainless steel, aluminum, copper, and specialty alloys for stamping and forming operations. - What is the typical lead time for a new transfer press?

Lead times vary by manufacturer and customization requirements but typically range from 3 to 9 months. Contact suppliers early to plan your equipment investment.

Get Expert Guidance and Compare Transfer Press Solutions

Whether you’re upgrading an existing stamping line, launching a new product, or seeking to automate your fabrication process, choosing the right transfer press is a strategic decision. Our resources, guides, and manufacturer directory are designed to help you:

- Compare product specs, capabilities, and application case studies

- Request quotes or detailed proposals from multiple suppliers

- Access technical support and process optimization advice

- Stay current on the latest transfer press innovations, trends, and best practices

Not sure where to start? Ask an expert about your stamping or transfer press application or browse the leading transfer press manufacturers now.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services